product

Pyrolysis technology offers a practical solution to recycling of used tires. The original raw materials to make tires which are:

are 100% recycled pyrolysis oil from used tyres and become usable products with marketing values. Tire to oil pyrolysis plant not only solves the environmental problem of used tires, but also create a profitable business with high ROI.

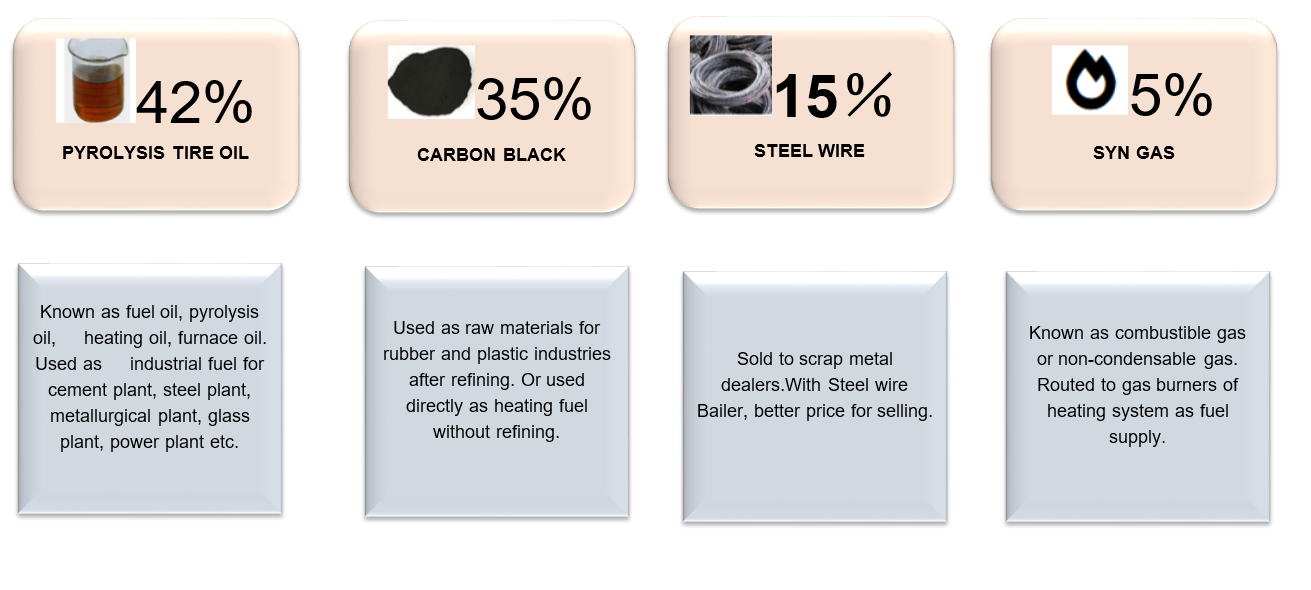

The production ratio of output products depend on the original component of waste tires.Below ratio for reference:

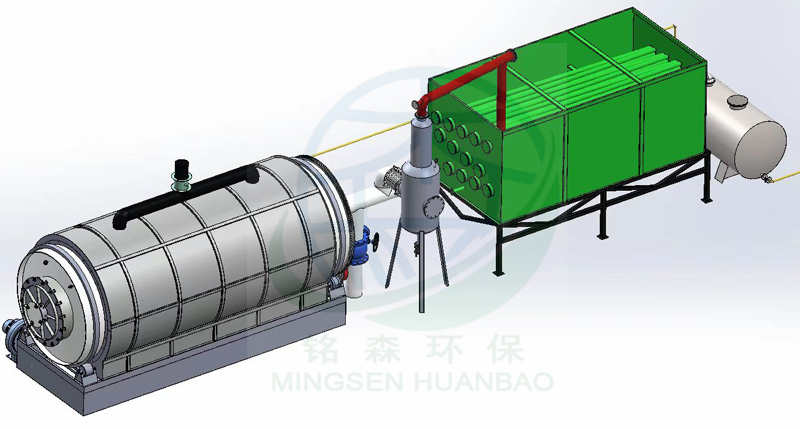

Put waste tyre in Auto feeder hopper with grappling, feed into reactor via Automatic Hydraulic Feeder, close the feeding door after finishing feeding.

Tyre oil or Non-condensible gas(Extra Non-condensible gas come from other pyrolysis machine running process) heating reactors evenly, after heating around 2 hours temperature up to 260℃,pyrolysis gas come out from oil gas outlet to condenser system to be oil, finally go to oil tank.

Waste tires break down into gas phase and solid phase under pyrolysis reaction. The gas phase enters condensing system becomes liquid fuel. The oil production process lasts 10 hours. The solid phase is carbon black waiting for discharging.

Cooling by blowers, Cool air in, hot air out, improve the cooling efficiency

After reactor cooling down to be lower than 80℃, open slag outlet, connect with automatic discharge machine, discharged carbon will be delivered to carbon warehouse via vacuum delivery system,ensure no dust fly out while discharging process.

Open feeding door, take out steel wire with our automatic steel wire discharging machine, equipped with dust extraction equipment while discharging steel wire, ensure no dust fly out while discharging process.

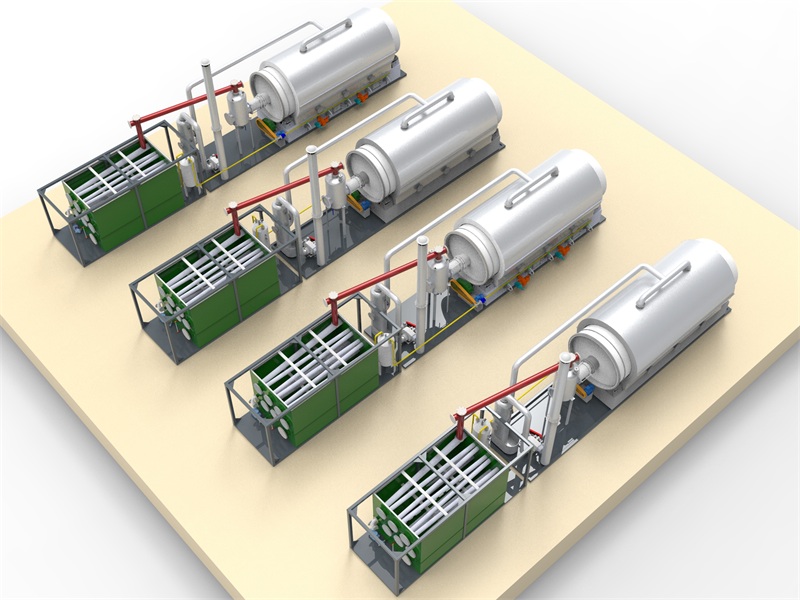

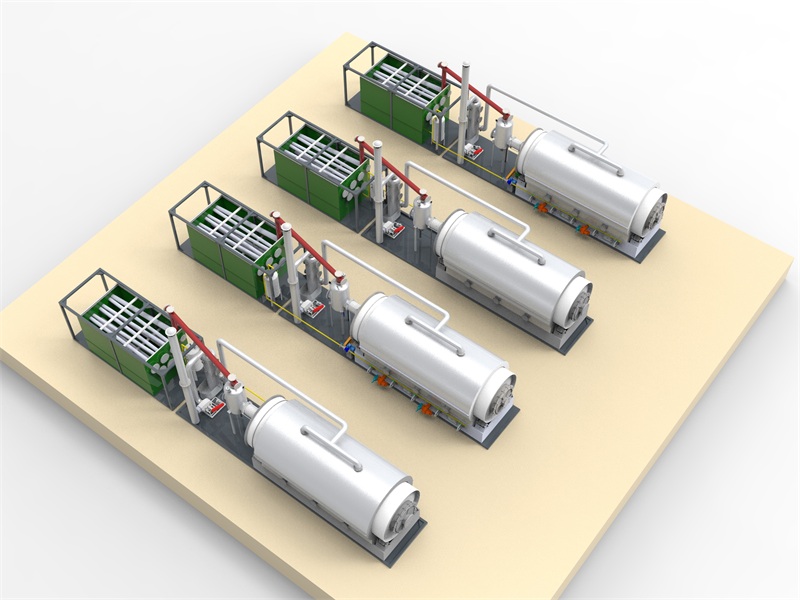

| BATCH TYPE PYROLYSIS DESIGE | SEMI CONTINUOUS PYROLYSIS DESIGN | FULLY CONTINUOUS PYROLYSIS DESIGN |

|  |  |

| Unit Capacity: 500KGS/5TPD/10TPD/15TPD/20TPD/30TPD | Unit Capacity: 500KGS/6TPD/12TPD/18TPD/25TPD/30TPD | Unit Capacity: 30TPD/50TPD/100TPD |

| Feedstock No need pretreated | Feedstock need pretreat | Feedstock need pretreat |

| Low machine cost for starting project | Medium machine cost for starting project | High machine cost for starting project |

| Need stop for cooling reactor | Need stop for cooling reactor(shorter time) | No Need stop for cooling reactor |

| More Info... | More Info... | More Info... |

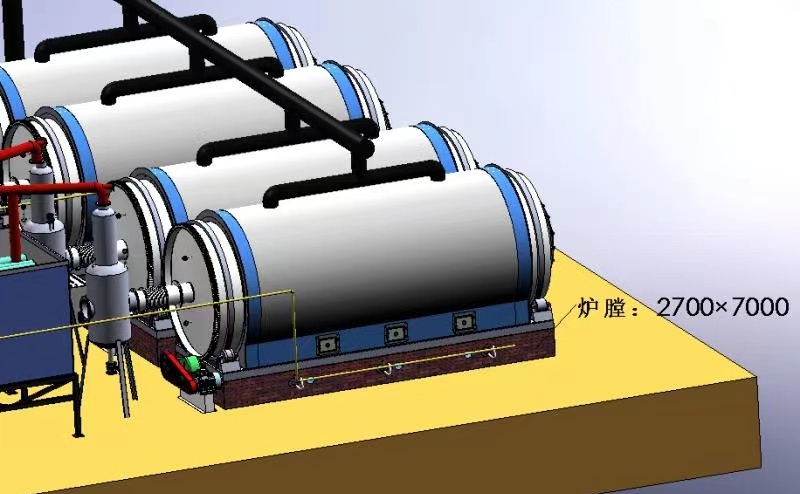

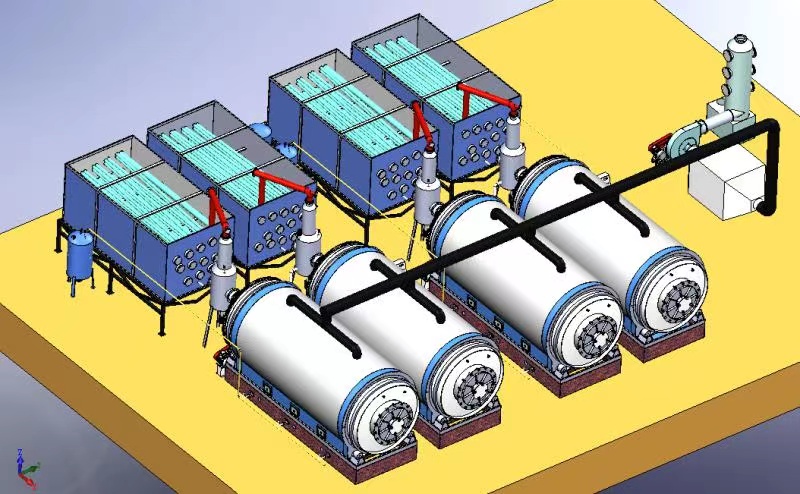

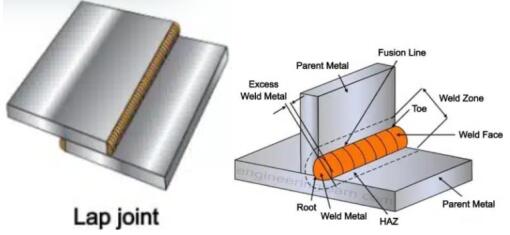

| ①Screw of Reactor Welding: We sincerely adopt the LAP WELDING, Welding Zone adopt the Spot Welding instead of full welding,which can effectively prevent the reactor tearing by expanding due to heat and contraction. | ②Insulation material for Cover: We adopted Ceramic fiber cotton can withstand high temperatures up to 1260 ℃,And use 304 sus welding rods for fixation, which has the advantages of high temperature resistance, non-falling off, fast heat dissipation, convenient transportation, and can advance the reactor cooling time by at least 2 hours. |

|  |

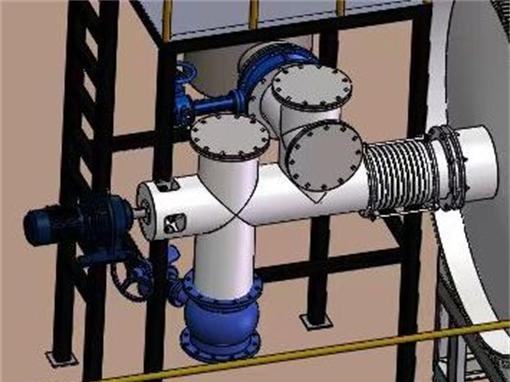

| ③Rollers:Adopt Model 351 big Roller,Since the reactor running with high temperature, we make the water-cooling tank for cooling down the roller for maximum utilization of the roller and extend its service life. | ④Ash Discharger from Gas Outlet:Eccentric ash discharging machine with large auger and off-center spiral blades, smoother air flow, no residual oil, preventing air blockage and pressure suppression, fast slag discharge, high efficiency, and safer. |

|  |

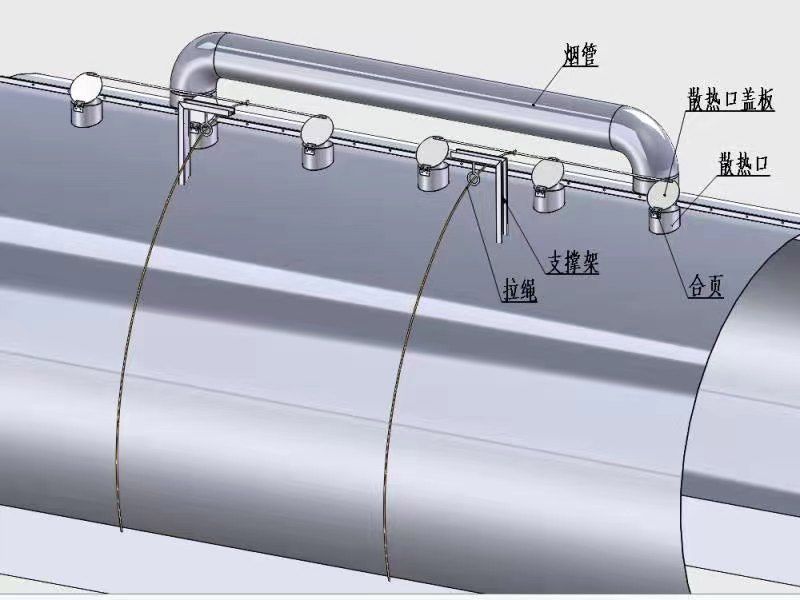

| High temperature Ball Valve: High temperature ball valve equipped after oil-separator, prevent flash explosion effectively, turn off the valve while discharging carbon, cut off the oil gas for avoiding air convection and flash explosion effectively. | Additional heat dissipation vents are added to the top of reactor. Allowing cooled air circulate into furnace, which can greatly reduce the reactor cooling time. |

|  |

| Double layer Water Sealing Tank: Double layer ensure safer working prevent back fire, and also can purify the syn gas before burning. | Reactor Sealing Way Updated: Sealed by sus304 for better sealing and durable using and good looking |

|  |