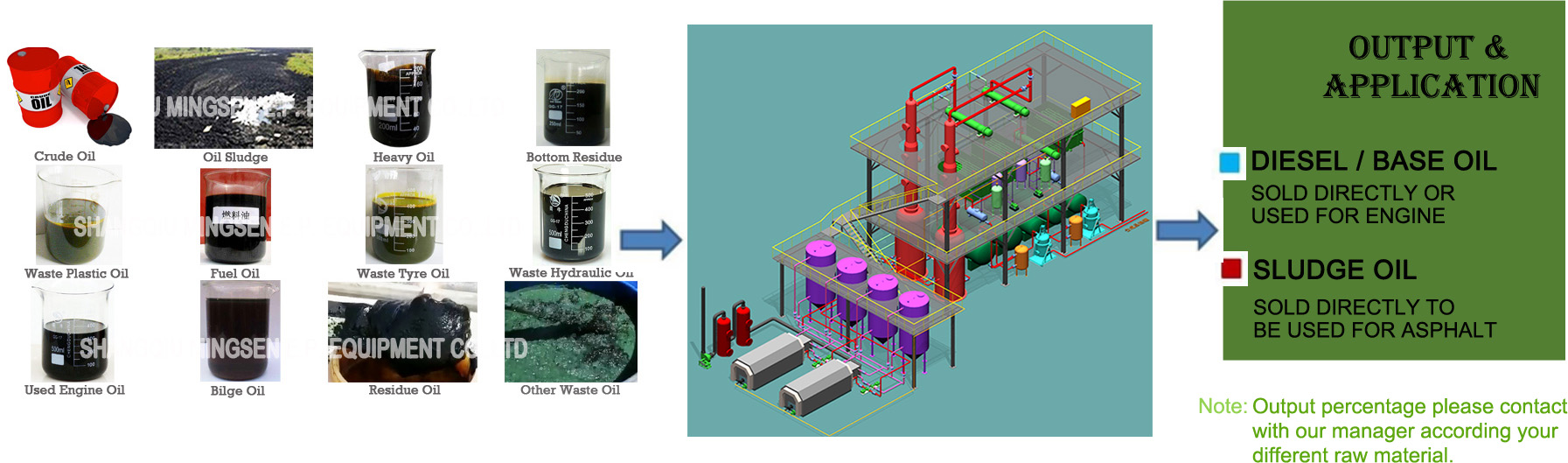

product

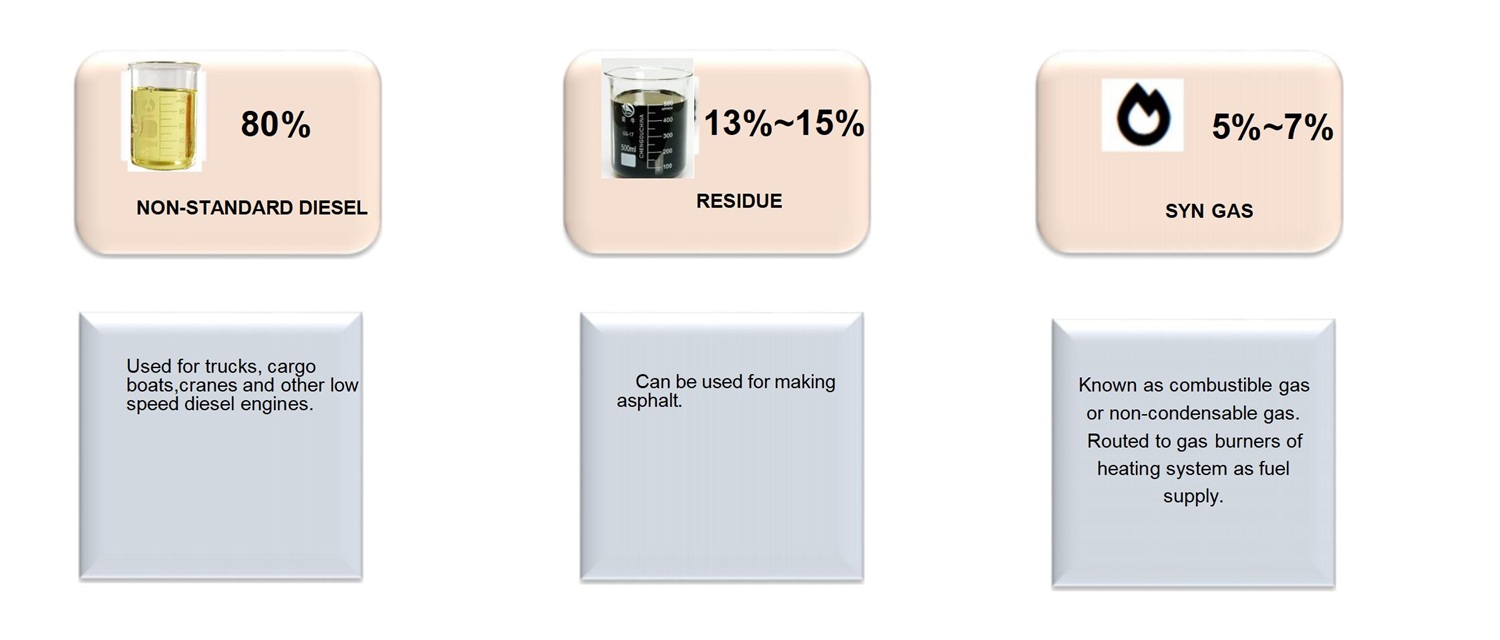

It is important to notice that pyrolsis oil price from pyrolysis plant is limited, better further refine it to get better recycling and better profit. A proper treatment technology allows to remove priority pollutants (polyaromatic hydrocarbons, toxic metals, chlorinated hydrocarbons) from pyrolysis oil.

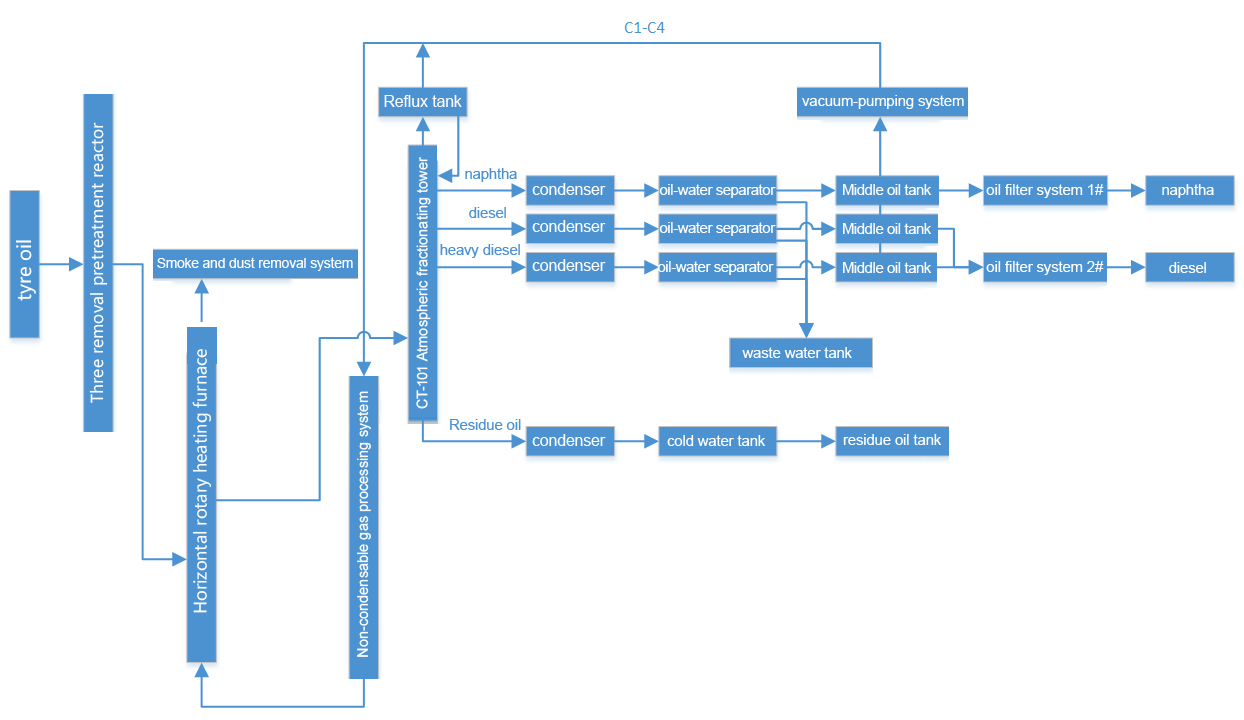

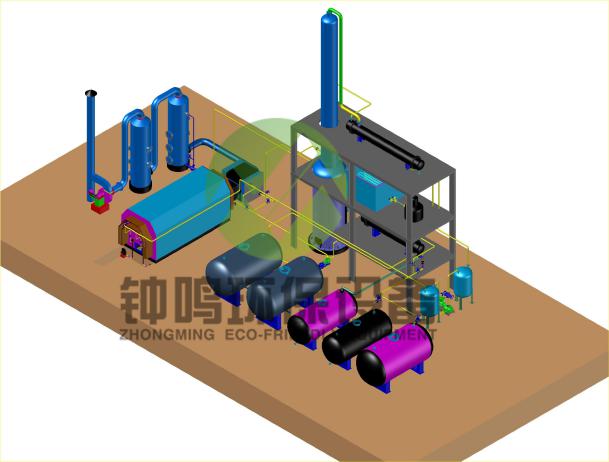

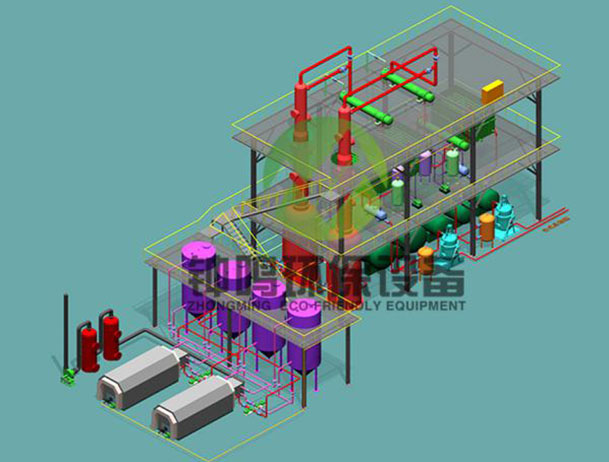

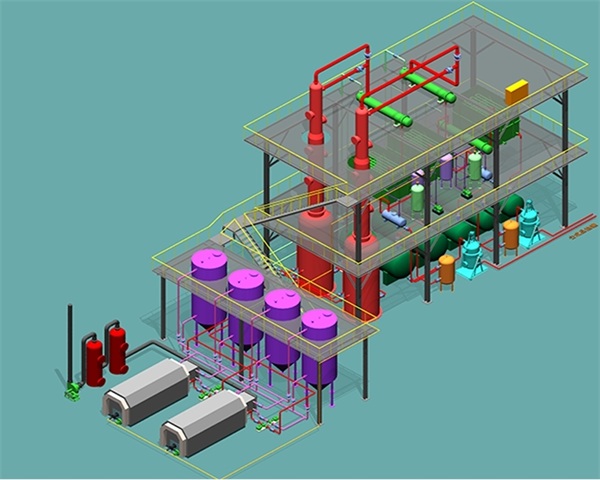

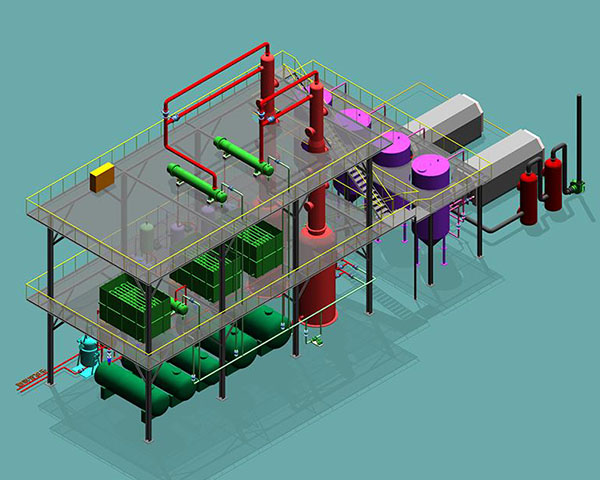

Pump raw oil into Pretreatment System through Automatic oil pump;

Remove Water,glue and other impurities to ensure end production quality;

Heating for Fractionating, Coal, Fuel Oil, Natural gas all can be used as heating fuel;

Second-time separate water and light naptha to ensure end production quality

Fractionating to get light diesel,diesel, heavy diesel and residue oil, Self-designed catalyst can be regenerated after , no second-time pollution.

Quartz filter, Activated carbon filter and homemade adding filter, for fixing color and smell to be as long as 8 months.

Not only save energy and economical, but also avoid pollution.

Treated by professional industry purification system before emission,ensure meet national standard emission requirement;

Flexible operating can get 2 different production, get it according market demand.

Note:

1) Non-condensible gas is the gas which couldn’t be liquefaction under normal pressure;

2)Oil-Water separating system included in whole machine set, 3 stage separation ensure end production oil meet standard.

| Different | NO.1 design | NO.2 design | NO.3 design |

| Design |  |  |  |

| Automatic | No | Semi-Automatic | Fully Automatic |

| Continuous | No | Semi-continuous | Fully Continuous |

| PLC Control | No | No | Yes |

| End Production Color | Looks Similar as Diesel | Looks Similar as Diesel | Same as Diesel |

| End Production Smell | Not Like diesel | Similar as Diesel | Same as Diesel |

| Diesel Standard | Nothing index meet standard | Some index meet standard | All meet Euro standard |

| Appearance After storage for few time | Color and smell will be same as tire/plastic oil after storage for few hours/days. | Color and smell will be same as tire/plastic oil after storage for few hours/days. | Diesel fixed color and smell can be kept as long as 6 months |

| Handling Process | Physical Reaction | Physical and Simple Chemical(like acid, alkali washing, white clay filter) Reaction | Gas catalysis, liquid catalysis and refining filtration |

| Usage | Heating as Furnace Oil | Boat,tractors which can adopt crude diesel | Power oil for engines and electric generator |

| Note:1. If want to know more difference, contact with us freely; 2.The yield and quality of the products obtained depends on the characteristics of the starting material. | |||

| ※MINGSEN Newst Distillation Technology is No.3 design, below all technical info based No.3 design. | |||

|  |

| *Adopt atmospheric pressure prefractionating, and vacuum distillation, catalytic cracking distillation, solvent refining, solvent extraction and other new technologies; | *Adopt self-designed professional catalyst, filtration composite materials and other innovative technologies to ensure product quality; |

| *Catalyst can be regenerated, no second time pollution to environment, increase end production yield; | *End Production quality meet Euro standard, based on processing used engine oil or plastic oil. |

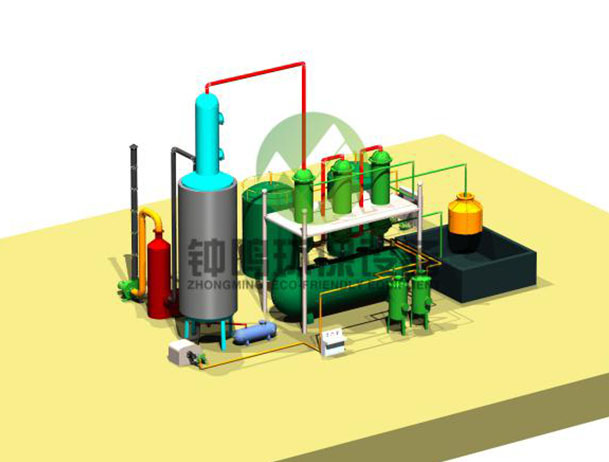

Shangqiu Mingsen factory introduction: