product

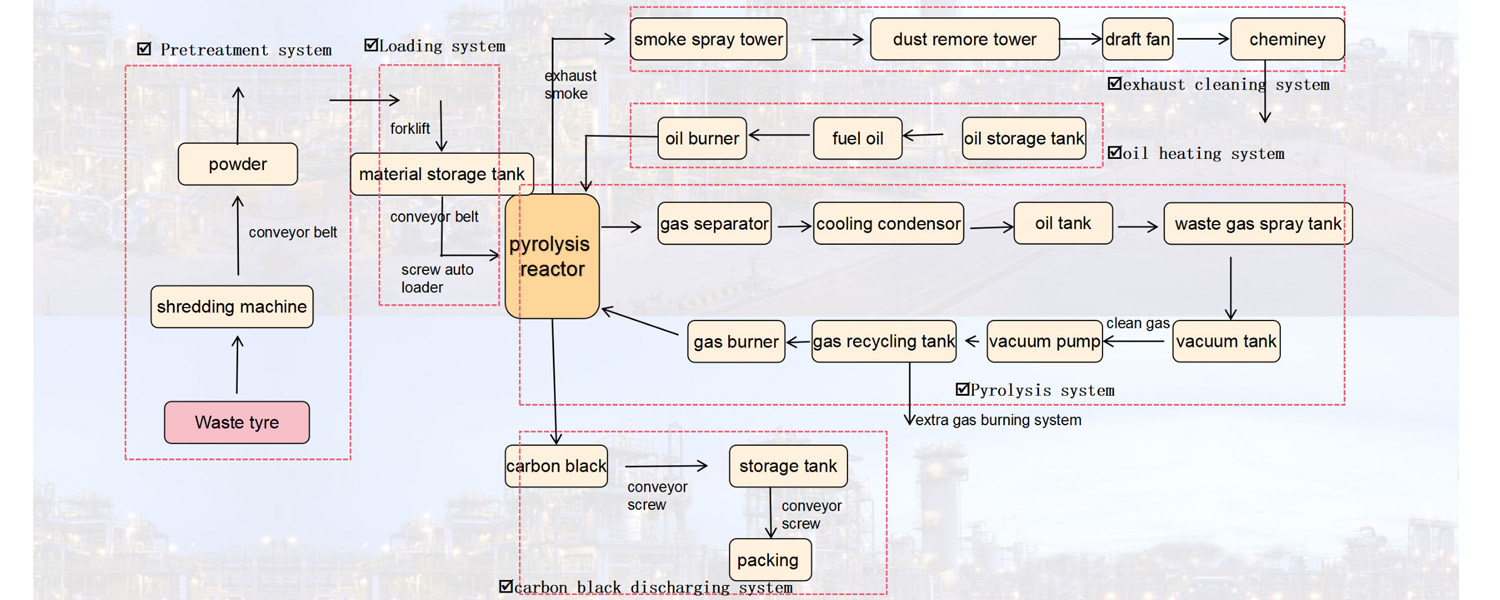

1.If your raw material is waste plastic/Aluminium Foil or other loosen waste, need firstly shredder it then Briquetting them to be required blocks

2.If your raw material is waste tyre/rubber, need shredder them to be required size.

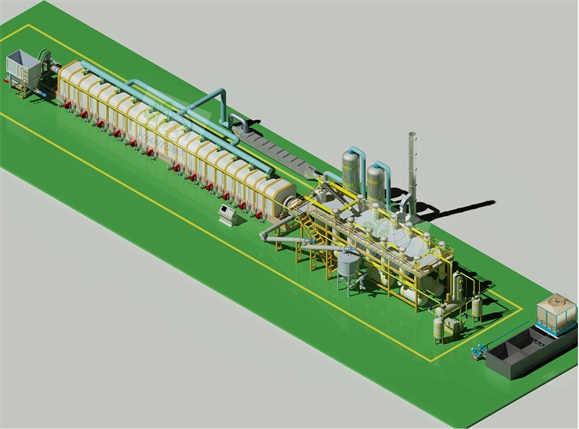

Through the storage hopper adjustable feeding device to below the main feeding device, the device to finish after compression, squeeze, preheating process into molten body.

First stage heating up to 200℃, dewatering, gasification, and recycling Condensible Gas;

Second stage heating up to around 450℃, recycle oil and carbon black.Then cool down carbon black and discharging. If carbon black need refinery, reactor temperature should heat up to 600℃. by this degree, carbon black can be activated.

Along with oil to oil tank, still have Syn gas(C1-C4), the gas will go to heating furnace for heating after treating by 2 layers water sealing system and 1 layer fire arrester system, fully burned via oil burner, by this way, Extra syn gas will be stored for sold or self heating, by this way, extra profit can be created.

Flue Gas cooling system: Firstly cool down the flue gas;

Cyclone Dust Remove System: First layer Remove Dust

Bag-type Dust Collector: Second layer remove dust

NOx Remove: Fully processing and burning to remove via Burners

Sulfur Content Remove: Sulfur remove system

Final achieve no any smoke can be see from the chimney outlet, and emission gas composition achieve American standard, and even better than this data.

Continuous feeding material, the other end of reactor continuous discharging carbon black, Carbon black water leg cooling system, vacuum discharging system and collecting system. With vacuum system, can prevent carbon black or dust leaking.

Continuous discharging metal material, normally finely crushed metal, dropped from carbon/metal outlet, carbon sucked away by vacuum system, heavy metal dropped down and delivered by magnetic separation system to briquetting machine to make blocks for easier transportation.

Note:

1) Non-condensible gas is the gas which couldn’t be liquefaction under normal pressure;

2) Vacuum Delivery System also named as Vacuum Pneumatic Deliverying System.

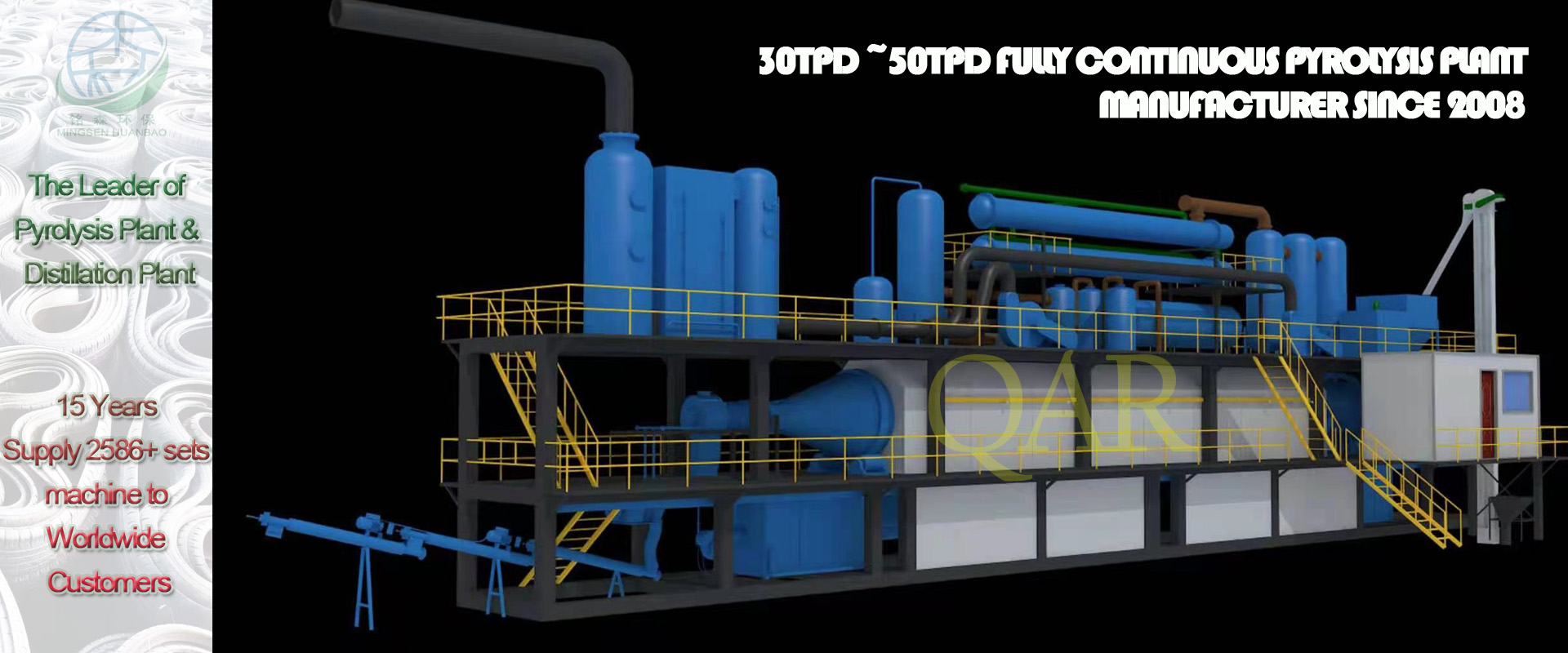

| BATCH TYPE PYROLYSIS DESIGE | SEMI CONTINUOUS PYROLYSIS DESIGN | FULLY CONTINUOUS PYROLYSIS DESIGN |

|  |  |

| Unit Capacity: 500KGS/5TPD/10TPD/15TPD/20TPD/30TPD | Unit Capacity: 500KGS/6TPD/12TPD/18TPD/25TPD/30TPD | Unit Capacity: 30TPD/50TPD/100TPD |

| Feedstock No need pretreated | Feedstock need pretreat | Feedstock need pretreat |

| Low machine cost for starting project | Medium machine cost for starting project | High machine cost for starting project |

| Need stop for cooling reactor | Need stop for cooling reactor(shorter time) | No Need stop for cooling reactor |

| More Info... | More Info... | More Info... |

| Different Item | Batch Type Design | Continuous Type Design |

|  | |

| Different Technology | Feeding by opening door, low production efficiency, has risk of safe or Eco-Friendly; | Fully Sealed Running based on safe and Eco-Friendly, Continuous Running without open door, feeding without oxygen; |

| Different Capacity | Per line Capacity maximum can process 10-12tons/24 hours, low running efficiency; | Biggest capacity for continuous running is 50-60tons/24 hours per line,high working efficiency; |

| Different Fuel Cost | Batch type design need stop and cooling down reactor before discharge carbon, then next batch starting will cost more fuel for heating up the reactor until oil gas produced. | Continuous Running allow feeding and discharging at anytime, no need coole down, no need waiting, greatly saved the fuel cost and time, running cost can be 20% less than batch type, especially recycle 90% syn gas and saved 70% fuel cost. |

| Different Feedstock Raw material size | No special required on the raw material size, less than 1600mm is Ok, low material preprocessing cost | Special required the raw material to be 1mm-50mm according different raw material, raw material need high preprocessing cost. |

| Eg. More different info welcome your further discussing~ | ||

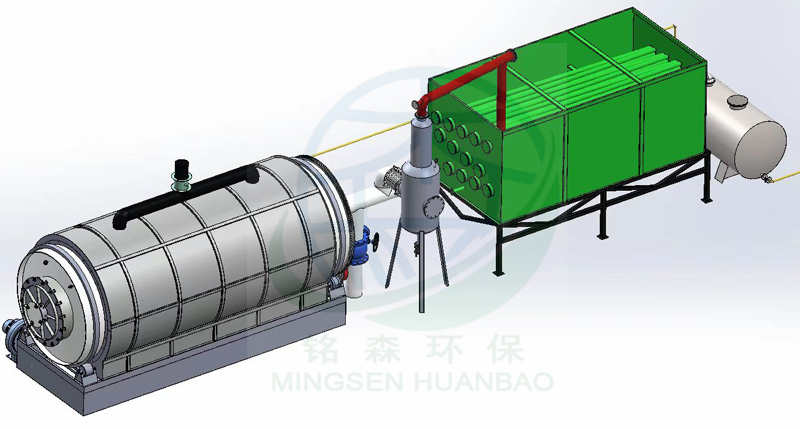

Fully-Continuous pyrolysis Machine Working Video:

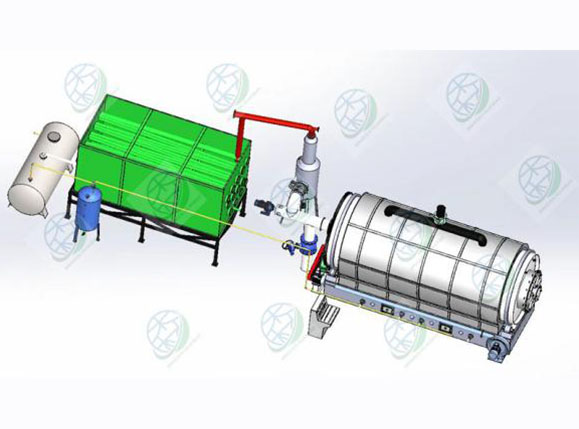

Pyrolysis plant for semi continuous-Heating pyrolysis working video:

Steel wire/Carbon Black Discharge System:

Shangqiu Mingsen factory introduction:

Pyrolysis working whole process video:

Factory Show verified by SGS