Along with the pyrolysis technology developed, and different waste material type shows on the market, pyrolysis plant manufacturers developed different pyrolysis machine design according customers’s various feedstock material type.

Choose different design according below few points:

- Project Budget

- Raw material different type, it is whole tire? Crushed rubber? Packed plastic? Or Flowable Sludge? Etc...

- Automatic or no need automatic? If local labor cost too high, can choose automatic design;

- How many tons waste can you get for running pyrolysis plant everyday?

- How about this project background? Personal investment or Government investment?

- Etc... if your requirement different with above points, please contact us.

Welcome your contact with us, our professional engineer will send you the detailed project proposal.

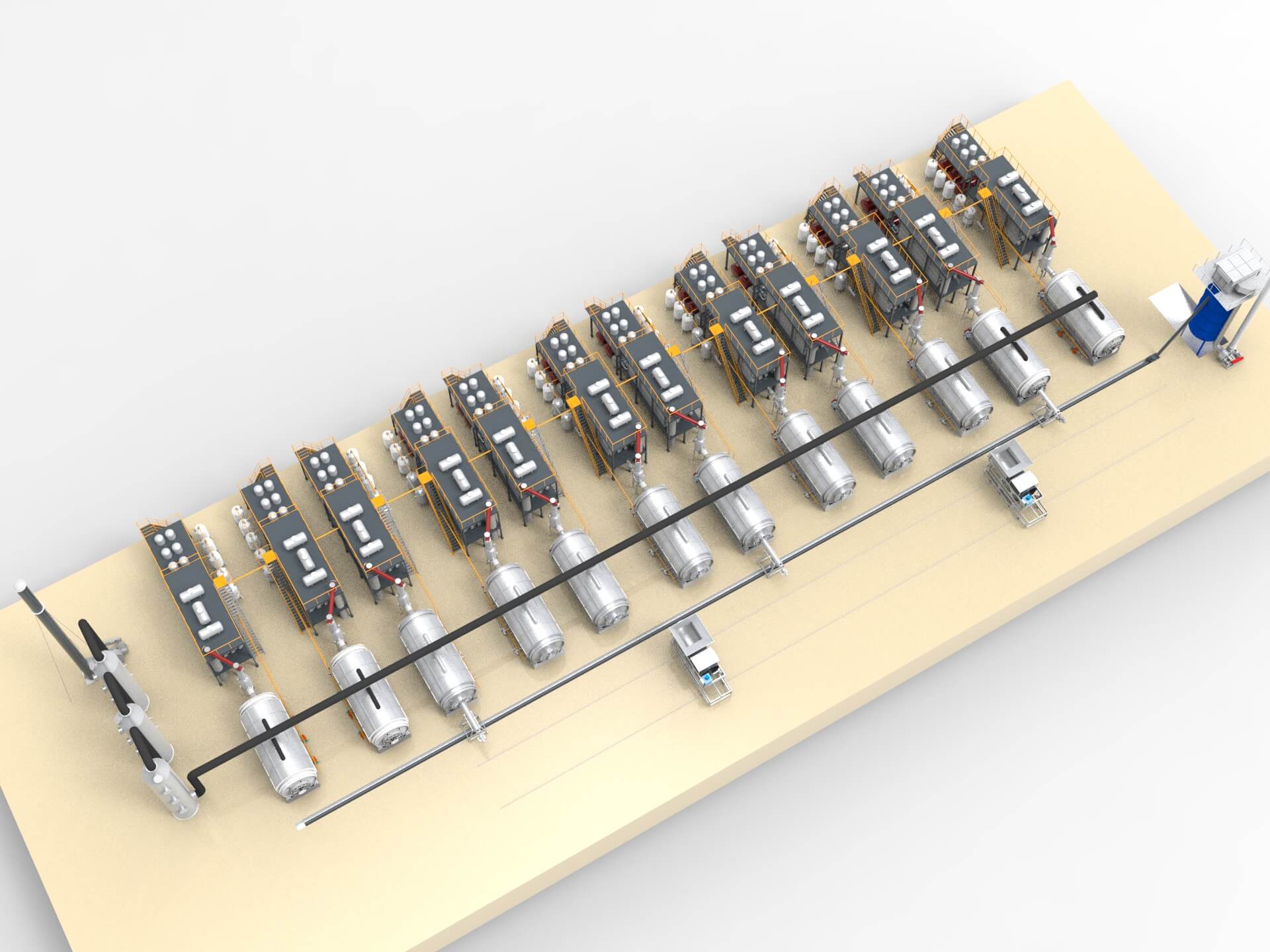

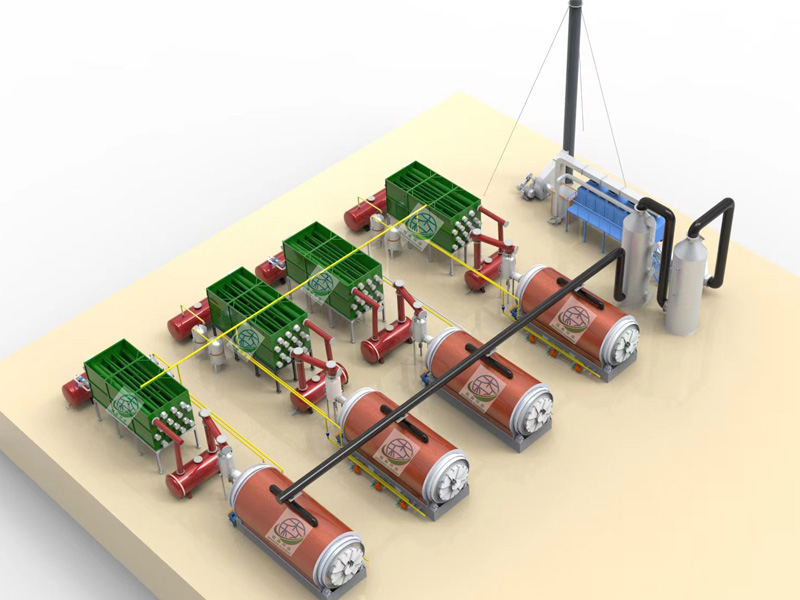

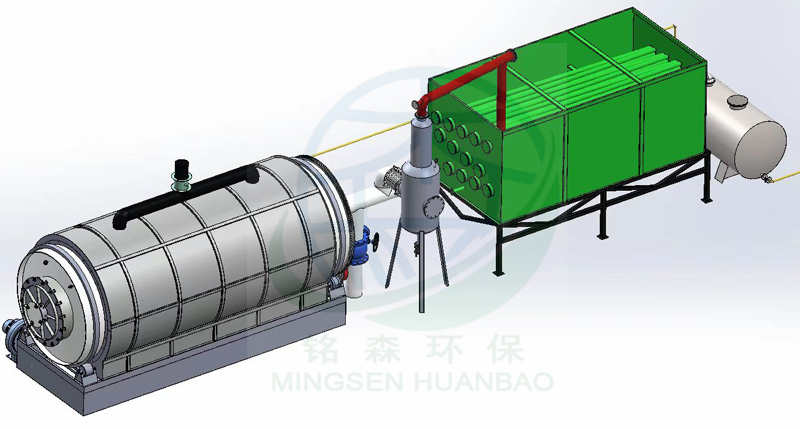

| BATCH TYPE PYROLYSIS DESIGE | SEMI CONTINUOUS PYROLYSIS DESIGN | FULLY CONTINUOUS PYROLYSIS DESIGN |

|  |  |

| Unit Capacity: 500KGS/5TPD/10TPD/15TPD/20TPD/30TPD | Unit Capacity: 500KGS/6TPD/12TPD/18TPD/25TPD/30TPD | Unit Capacity: 30TPD/50TPD/100TPD |

| Feedstock No need pretreated | Feedstock need pretreat | Feedstock need pretreat |

| Low machine cost for starting project | Medium machine cost for starting project | High machine cost for starting project |

| Need stop for cooling reactor | Need stop for cooling reactor(shorter time) | No Need stop for cooling reactor |

| More Info... | More Info... | More Info... |